HAGENS

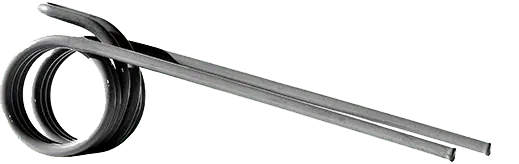

Pick-up springs

A pickup spring can be supplied in a thickness of up to 18.0 mm.

A pickup spring is generally surface treated but Hagens is happy to recommend other options.

How does pickup springs work

Pickup springs are often surface treated eg. paint but also other treatments can be added.

Pickup spring are often used in agricultural machinery – eg. combines and straw-balers.

Contact us

Are you looking for an specific solution? Get in touch.→

Pick-up springs tailored for agricultural efficiency

At HAGENS, we manufacture robust pick-up springs designed for high-performance agricultural machinery. With a thickness of up to 18.0 mm, these components are engineered to endure repetitive motion and heavy mechanical load – essential features for reliable function in demanding field conditions.

Pick-up springs are commonly used in equipment such as combines, straw-balers, and other harvesting systems. Their purpose is to manage and guide crop flow efficiently while absorbing shocks from uneven terrain. To ensure durability and reduce wear, pick-up springs are generally treated with a protective surface finish, most often paint. Alternative treatments can be recommended depending on usage environment and customer requirements.

Thanks to HAGENS’ advanced production capabilities and decades of experience, each pick-up spring is manufactured with precision and attention to functional details. We work closely with customers to determine the appropriate specifications, including dimensions, load capacity, and treatment options, to match each application.

Our production setup in Denmark and China enables us to provide consistent quality and flexible delivery options, whether you require standard parts or a tailored solution. In every case, documentation and process control meet the same high standards you can expect across all our product categories.

For agricultural applications where performance and durability are critical, HAGENS is your trusted partner for reliable pick-up spring solutions – made to perform in the field, season after season.

Spring types

Compression springs – Tension springs – Pick-up springs – Torsion springs

Clock springs – Disc springs – Die springs – Wave Springs