Compression springs manufacturer

Different-sized compression springs

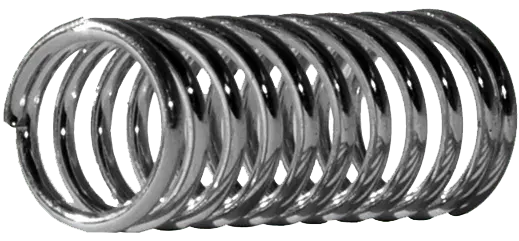

Compression springs – from 0.1 mm to 25.00 mm wire diameter. Galvanized, painted or finished in some other way.

Leading compression spring manufacturer

HAGENS is a leading compression spring manufacturer, offering a diverse range of sizes and designs to meet the unique requirements of our customers. Our portfolio includes small compression springs for precision applications and heavy-duty compression springs for demanding industrial tasks.

Each compression spring is designed to endure the required forces and weights. Whether used for static or dynamic loads, the materials and construction are tailored to the application, ensuring maximum performance and durability.

Contact us

Are you looking for an specific solution? Get in touch.→

Production: Springs directly to the customer

HAGENS Spring Group stands out as one of the top compression springs manufacturers due to our efficient production processes and cutting-edge equipment. We provide competitive pricing without compromising on quality.

We offer a variety of surface treatments to meet specific needs, such as:

- Shot peening for enhanced fatigue resistance.

- Galvanizing for corrosion protection.

- Delta treatments and painting for specialized applications.

Packaging and delivery are tailored to each customer. Whether you require standard packaging or custom-branded solutions, we ensure a seamless process. With headquarters in Støvring, Denmark, and additional production facilities in Ningbo, China, we are strategically positioned to serve customers worldwide.

Springs require the right raw material

The performance of any compression spring begins with the right materials. HAGENS collaborates with leading steel mills to source high-quality raw materials suited to tensile strength and spring applications. Common materials include:

- EN 10270-1: Cold-drawn wires for general-purpose compression springs.

- EN 10270-2: Oil-tempered wires for high-stress applications, such as valve springs.

- EN 10270-3: Stainless wires for corrosion-resistant uses.

For specialized industries like oil and gas, marine, and food production, we provide advanced materials such as Elgiloy®, Hastelloy C-276®, and Inconel® X-750. These materials ensure longevity and reliability, even under extreme conditions.

Custom compression springs

HAGENS excels at producing custom compression springs to meet specific customer needs. Each order is tailored based on the required dimensions, raw material, and finish. For example:

- Small compression springs are often used in door locks and precision tools.

- Heavy-duty compression springs are essential in marine engines and industrial machinery.

Our offerings range from springs with a wire diameter as small as ø0.2 mm to large springs with a diameter of ø25.0 mm. Depending on the application, springs can be galvanized, painted, or finished to customer specifications. Each component is engineered to meet both mechanical performance and visual appearance requirements in demanding industrial environments. As a compression springs manufacturer, HAGENS ensures that every design meets the specific functional and environmental demands of the application.

Quality assurance and sustainability

All springs produced by HAGENS adhere to ISO 9001 and ISO 14001 certifications, ensuring compliance with international quality and environmental standards. Production follows strict documentation procedures, including raw material tracking and equipment usage reports.

We also implement TS16949 principles, providing customers with detailed reports on material inspections, production cycles, and testing. This commitment to quality makes us a trusted compression spring supplier.

Why choose HAGENS for compression springs?

As one of the top compression springs suppliers, HAGENS offers:

- Custom solutions for small compression springs and heavy-duty compression springs.

- Expertise in producing springs for various industries, from automotive to marine.

- Advanced surface treatments and packaging tailored to customer needs.

- Reliable global delivery and support.

Whether you’re looking for a small compression spring, a heavy-duty compression spring, or a custom solution, HAGENS Spring Group is your trusted partner.

Spring types

Compression springs – Tension springs – Pick-up springs – Torsion springs

Clock springs – Disc springs – Die springs – Wave Springs