Tension/extension springs manufacturer

Tension springs for many purposes

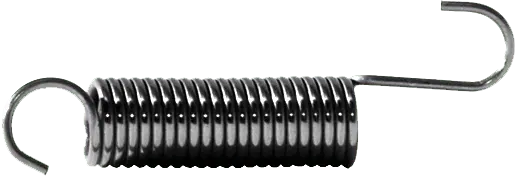

A tension spring can have a wire diameter from 1.0 to 25.0 mm. Tension springs are supplied with all types of loops,

hooks or with a threaded insert.

Tension springs for many purposes

Tension springs play a vital role in countless mechanical applications. At HAGENS, we specialize in producing high-quality tension springs, designed to meet a wide range of needs. From small tension springs for precision applications to high tension springs for industrial machinery, we are committed to delivering exceptional products.

Contact us

Are you looking for an specific solution? Get in touch.→

Tension springs directly to the customer

HAGENS Spring Group takes pride in offering tension springs that are manufactured efficiently and delivered promptly to our customers. Our advanced production facilities and state-of-the-art equipment allow us to maintain a reputation as one of the leading tension spring manufacturers.

We provide customized solutions, including various surface treatments to enhance the durability and performance of our springs. Options include:

- Shot peening for increased fatigue strength.

- Galvanizing for corrosion protection.

- Delta treatments and painting for specialized applications.

Additionally, we offer flexible packaging and delivery solutions tailored to individual customer needs. Whether you require springs packed in standard materials or delivered in your own branded packaging, we ensure the process is seamless.

With headquarters and production facilities in Støvring, Denmark, and additional production capacity in Ningbo, China, we maintain a global presence while staying close to our customers.

Springs require the right raw materials

At HAGENS, the foundation of our superior tension springs lies in the selection of high-quality materials. We work with industry-leading steel mills to source materials that meet specific demands for tensile strength and spring performance.

Our most commonly used materials include:

- EN 10270-1: Cold-drawn spring wires for general-purpose tension springs.

- EN 10270-2: Oil-tempered wires for high-stress applications like valve springs.

- EN 10270-3: Stainless spring wires for corrosion resistance in demanding environments.

For industries such as oil and gas, marine, and food production, we utilize advanced materials like Elgiloy®, Hastelloy C-276®, and Inconel® alloys to meet strict performance requirements. These advanced alloys are selected for their ability to withstand harsh environments, including exposure to chemicals, moisture, and extreme temperatures. Our specialists collaborate with customers to ensure each material choice supports long-term reliability and optimal performance in demanding applications.

Diverse applications for tension springs

HAGENS supplies tension springs for a wide range of uses, including:

- Garage door spring tension systems designed for reliability under constant load.

- Small extension springs for trampolines and consumer goods.

- High tension springs for agricultural and industrial machinery.

- Automotive components, pliers, and other precision tools.

No matter the application, we work closely with our clients to ensure each tension spring is optimized for its intended purpose.

Why choose HAGENS?

As trusted tension springs suppliers, HAGENS offers:

- Custom design and manufacturing of tension coil springs and small extension springs.

- Comprehensive quality control systems, including ISO 9001 and ISO 14001 certification.

- Detailed documentation and traceability of raw materials and production processes.

- Competitive pricing without compromising quality.

Whether you need a replacement tension spring or a bespoke solution, HAGENS Spring Group is your partner for reliable and efficient spring solutions.

Spring types

Compression springs – Tension springs – Pick-up springs – Torsion springs

Clock springs – Disc springs – Die springs – Wave Springs