HAGENS

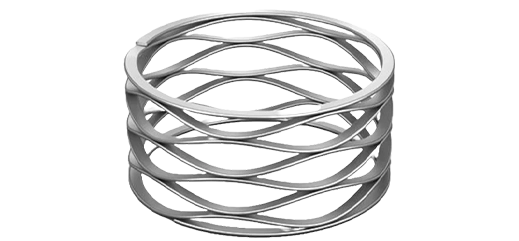

Wave Springs

Wave springs have been developed as an alternative to the traditional compression spring.

When are wave springs used?

A wave spring is normally used when space for the spring is limited.

Both the wave spring’s collective length and the spring’s height are significantly less than a compression spring with the same strength.

Typically a wave spring will fill a very small space in comparison to the function that the spring is performing. Such springs are generally used where there are narrow axial and radial space restrictions. But they can also be used in other contexts.

Contact us

Are you looking for an specific solution? Get in touch.→

Other uses for wave springs

Wave springs in several layers are produced from a flat spring wire and are supplied in various sizes and several different materials. A wave spring in one layer is typically manufactured in round spring material.

Regardless of the size, Hagens Spring Group supplies wave springs based on the customers specifications and strength requirements.

At the end of the day it is dependent on what the spring will be used for, and we are happy to help you find the correct spring solution.

We also provide custom wave spring solutions

Tailored wave spring solutions from Hagens

At Hagens, we specialize in the development and manufacturing of high-performance wave springs tailored to the specific needs of our customers. With decades of experience in spring technology and advanced metal forming, we are a trusted supplier to industries where space constraints, precision, and reliability are crucial.

Wave springs are designed to deliver the same force as traditional compression springs but within a significantly smaller axial space. This makes them ideal for compact mechanical assemblies across sectors such as automotive, electronics, medical devices, and industrial machinery. Whether you require single-turn, multi-turn, or nested wave springs, we deliver customized solutions that meet your exact technical specifications.

Engineered for precision and performance

All wave springs from Hagens are produced using high-grade materials and advanced manufacturing techniques, ensuring consistent quality, fatigue resistance, and long service life. We collaborate closely with our clients through every phase – from concept and design to prototyping and series production – to ensure the right fit for every application.

In addition to standard dimensions, we offer custom geometries, surface treatments, and material choices to support unique performance requirements. No matter the complexity or scale, Hagens ensures that every solution is built for function, efficiency, and durability. Our production approach combines flexibility with rigorous quality control, enabling us to meet even the most specialized technical demands. This ensures that each component integrates seamlessly into your system, delivering consistent results from day one.

Your partner in spring innovation

As a global supplier, Hagens delivers not just springs, but reliable partnerships. Our focus on quality, innovation, and customer collaboration makes us a preferred partner for companies looking for advanced mechanical solutions. That is why our wave springs are trusted across industries where compact design, high performance, and long-term reliability are essential to the success of complex mechanical systems.

Need assistance with choosing the right wave spring? Our team of engineers is ready to support you in finding a spring design that meets your mechanical, spatial, and material requirements.

Let’s shape your next solution – together.

Spring types

Compression springs – Tension springs – Pick-up springs – Torsion springs

Clock springs – Disc springs – Die springs – Wave Springs