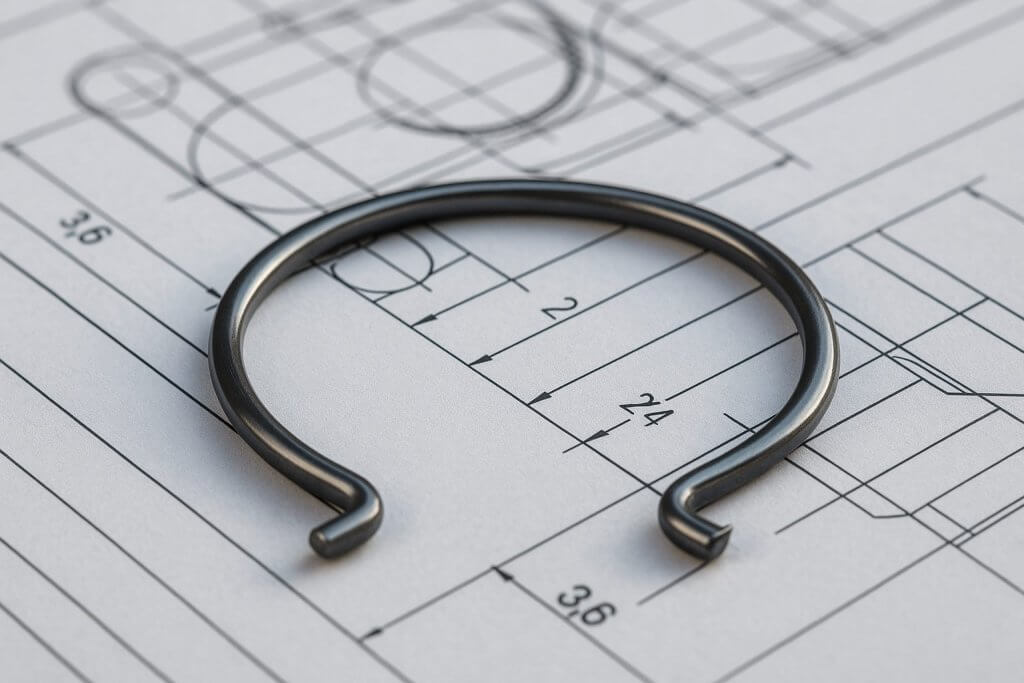

Mechanical assemblies rely on precise retention to keep components stable, aligned and functioning as intended. Locking rings are essential in this context, as they secure bearings, seals and rotating parts in place without adding unnecessary bulk or complexity to the system. Hagens develops and manufactures locking rings in customer-specific configurations, enabling each ring to match the functional, mechanical and environmental conditions of its intended application.

Engineering tailored for system integration

Every locking ring is produced according to the required retention force, installation method and long-term operating conditions. Dimensions, material selection and tolerances are defined in close dialogue with engineers and designers to ensure reliable performance throughout the component’s lifecycle. This approach allows the ring to be designed into the full system rather than added late in the process, reducing the risk of assembly issues, uneven load distribution or premature wear.

When developing a customised locking ring, considerations typically include groove geometry, thermal expansion, vibration exposure and assembly methods—manual or automated. The result is a component calibrated to provide predictable mechanical behavior in the environment where it will operate.

Precision across production sites

Locking rings are produced across Hagens’ international manufacturing setup, ensuring consistent quality and documentation for customers across sectors such as rail, offshore, medical technology and industrial machinery. Production follows identical standards at all sites, ensuring that material certifications, tolerances and surface requirements remain uniform regardless of volume or location.

This structure enables both rapid prototyping and scalable high-volume production, supporting customers from early development stages through to long-term supply.

Suggested reading: When a clock spring is the right choice over a torsion spring

Quality and mechanical reliability

Because locking rings serve as critical retention elements, mechanical performance is verified through thorough dimensional and functional testing. Retention force, elasticity, deformation limits and resilience under vibration are assessed before approval. Surface finish is also central to performance, particularly in medical or food-related applications where hygiene and documentation requirements are strict. In harsher environments such as offshore or transportation systems, the focus shifts to corrosion resistance and fatigue behavior.

Through controlled processes and verified material selection, each locking ring maintains stable performance even under fluctuating loads and extended service intervals.

Integration in industrial design

Locking rings are applied anywhere components must remain securely positioned during operation. They are typically used in gearboxes, motors, pumps, valves and rail systems, where movement, vibration and thermal variation place significant demands on retention components. As part of their custom spring solutions, Hagens adapts each locking ring’s geometry and material properties to ensure stable retention under these varying mechanical conditions

Engineers integrate locking rings into designs to prevent axial displacement, maintain alignment and support smooth operation of rotating assemblies. Their compact geometry makes them suitable for applications with limited installation space, while their customisability allows precise alignment with groove dimensions and mating components.

Working with locking rings early in the design phase offers additional advantages, allowing optimisation of part geometry, groove depth and installation clearances. This reduces assembly time and supports long-term durability of the overall mechanism.

Durability and lifecycle performance

Hagens manufactures locking rings using materials selected for durability, stability and documented performance. Requirements vary across sectors: medical devices rely on controlled surface finish and traceability, while transportation systems require resilience under shock loads, vibration and seasonal temperature changes. Offshore and energy-related applications typically demand enhanced corrosion resistance and robust fatigue properties.

These material and process considerations support long service life and consistent retention force, reducing maintenance needs and contributing to reliable system performance.

Sustainability and responsible production

Hagens maintains a production framework built on internationally recognised standards, including ISO 9001 and ISO 14001. Continuous improvement in resource use, documentation and environmental impact supports sustainable product development throughout the value chain.

This commitment ensures that locking rings meet both mechanical requirements and broader expectations for responsible manufacturing.

The role of locking rings in modern industry

Across industries, locking rings play a central role in safeguarding the performance of mechanical systems. Their ability to retain components reliably under varying loads makes them indispensable in assemblies where failure is not an option. Combined with decades of engineering experience and coordinated global production, Hagens delivers locking ring solutions that meet the technical, environmental and operational demands of modern industry.

Through close collaboration and customised engineering, each ring is designed to maintain stability, alignment and long-term reliability—cycle after cycle.