Most people never see them. Tucked inside electrical panels, buried within automotive assemblies, or bolted behind building cladding — precision stamping parts do their job invisibly. But when one of these components is off by even a fraction, the consequences can range from a minor malfunction to a complete system failure.

That is why tolerances matter. Not as a technical footnote, but as the defining characteristic that separates a stamping part that works from one that doesn’t.

What Makes a Stamping Part “Precision”?

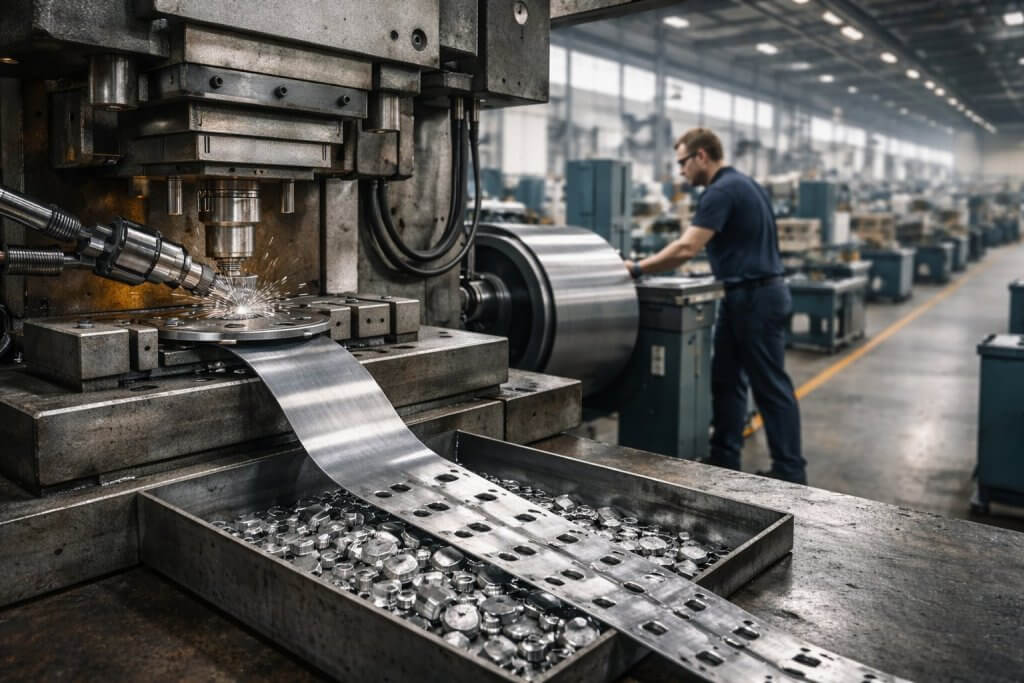

All stamping parts begin the same way: a metal sheet is fed from a coil through a stamping press, where it is cut, bent, or formed into a specific shape. The difference between a standard stamping part and a precision stamping part lies in how tightly the finished component matches the intended design — and how consistently that match is repeated across thousands or even millions of units.

In applications where stamped metal parts are used in electrical and technical machinery, even the smallest deviation can cause technical failure. A screw terminal that doesn’t clamp properly, a brake wear indicator that triggers too early or too late, a building component that doesn’t align with its fixture — these are all tolerance problems.

Precision stamping parts are defined by their ability to hold tight tolerances repeatedly, across every unit, every batch, and every production run.

The Role of the Stamping Process

Achieving tight tolerances starts with the process itself. At HAGENS, metal sheet is run directly from the coil through the stamping press. This coil-fed approach helps maintain material consistency, since the sheet is continuous rather than cut into blanks that might vary.

After stamping, most metal sheets are re-coiled for future use. This is not just an efficiency measure — it also reduces material waste, since stamped steel parts can be produced and shaped to fit even the smallest requirements.

The stamping press parts themselves are configured precisely to ensure repeatability and long-term tool performance. When the tooling is right, each stamped component comes out identical to the last. When it drifts, even slightly, you lose that consistency — and with it, the precision that the application demands.

For components like screw terminals, HAGENS integrates secondary operations directly on the stamping machines. Thread cutting and screw insertions happen in-line during the stamping process rather than as separate steps afterwards. This reduces handling, eliminates alignment errors between stations, and keeps tolerances tight throughout.

Also read – The difference between standard compression springs and heavy-duty compression springs

Why Tolerances Matter More in Some Industries Than Others

Not every stamping part requires the same level of precision. A decorative bracket has different requirements than a component inside a braking system.

In automotive applications, stamped metal parts must function correctly under heat, vibration, and constant mechanical stress. HAGENS supplies automotive metal stamping parts for applications including sunroofs, engines, hoods, and seat belt systems — all areas where a dimensional error can compromise safety. The company holds IATF 16949 certification, the automotive industry’s own quality management standard, which governs how precision stamping parts for vehicles are manufactured and controlled.

In electrical and technical machinery — where HAGENS reports the majority of its stamping output is used — tolerances determine whether a connection is secure, a circuit is reliable, or a component fits its housing. Screw terminals, for instance, must allow a wire to be clamped securely under a screw head or within a metal tube. If the stamped part is even marginally off-spec, the electrical connection may be loose, intermittent, or unsafe.

Construction and marine applications add environmental demands. Stamped metal parts in these sectors must not only be dimensionally accurate but also withstand specific elements and abrasion over long service lives. Brake wear indicators manufactured by HAGENS serve not only motor vehicles but also wind turbines, cranes, and heavy-duty manufacturing equipment — environments where replacement is costly and failure is not an option.

Quality Control: Where Precision Is Verified

Manufacturing to tight tolerances means nothing without verification. At HAGENS, quality control operates at three stages: incoming raw materials, during production and finishing, and a final check before any product leaves the facility.

The production facilities include automatic quality inspection systems, and the company can supply documentation from material certificates through to full PPAP documentation — the Production Part Approval Process used widely in automotive supply chains. Specific testing capabilities include salt spray testing for corrosion resistance, life cycle durability testing, relaxation testing, CMM measurements (Coordinate Measuring Machine, which verifies dimensional accuracy in three dimensions), and tensile strength testing.

HAGENS holds five certifications that apply across its product lines: ISO 9001 for quality management, ISO 14001 for environmental management, ISO 45001 for occupational health and safety, IATF 16949 for automotive quality, and ISO 13485 for medical devices. All production facilities — across Denmark, Sweden, Hungary, and China — maintain identical technical and quality standards.

No product leaves HAGENS before it is checked. That principle applies equally to a batch of ten and a batch of ten thousand.

Also read – When a Clock Spring Is the Right Choice Over a Torsion Spring

Consistency at Scale

One of the practical advantages of precision stamping is its scalability. Once the tooling is set and validated, the stamping process enables consistent replication — making it ideal for industries where identical units are required at scale.

HAGENS handles both low and high volumes, which reflects a reality of precision stamping: the tolerance requirements don’t change with order size. A short prototype run demands the same dimensional accuracy as a long production run. The difference is in setup and tooling economics, not in the precision of the finished part.

Complex shapes can be formed efficiently through stamping while ensuring structural consistency across high-volume production. This is particularly relevant for customers who need custom stamped metal parts — components designed for a specific application rather than pulled from a standard catalogue. HAGENS constructs and manufactures its stamping tools in-house, which gives the company direct control over tooling quality and the ability to fit machines to run customer items with high performance and throughput.

The Invisible Standard

Precision stamping parts will never be glamorous. They sit inside machines, behind panels, underneath housings. Most people will never see them, and the best ones will never give anyone a reason to look.

That invisibility is the point. When tolerances are held, when the stamping process is controlled, and when every part is verified before it ships — the component simply does its job. Quietly, reliably, and exactly as designed.

For the industries that depend on these parts — from automotive to electrical machinery to construction — that silent reliability is not a detail. It is the entire requirement.